ARE YOU PREPARED TO RISK THE ALTERNATIVE ?

About Us

It is the intention of Prime Composites Australia Pty Ltd to create a positive memorable experience each and every time with every contact, whether customer, supplier or team member.

Company

Prime Composites is located at Arundel on the Gold Coast.

We are a family owned and operated small business, so we are able to offer old fashioned customer service and backup and we take the time to listen to our customers.

Contact us now! 07 5500 5300

Prime Composites on the Gold Coast and have been producing light weight structural composite parts for over 40 years, one of them that you may be familiar with is the Hume-King floodgate.

WE HAVE NOTICED THE PROBLEM

- Steel covers will rust when exposed to saltwater or coastal climates

- Steel covers will rust when exposed to common sewer gases

- Steel covers will rust when exposed to wastewater and commonly disposed chemicals found in wastewater.

- Steel & concrete covers are heavy and cause risk of occupational injuries

- Steel & concrete covers crack & break making them dangerous and unsightly.

Prime Composites Class B & D Access Covers is the Solution

PRIME Covers and Surrounds are made totally from fiber composite materials (glass fibers and polyester resin) As you can see from the sample cross sections it is solid. There are no metal, plastic or timber reinforcements which can breakdown and DE-laminate over time causing catastrophic results.

Because the cover and surround are both fiber composites and are corrosion resistant they do not bind together making it quicker, easier and safer to remove lids. They are also UV stable and resistant to a large range of chemicals.

Prime Covers have undergone load testing at the University of southern Queensland (Composite Structure testing facility) and they have surpassed the load requirements of the AS3996.Our new class B&D Access Covers accept the lifting key referred to in the AS3996 and weigh 22 & 29 kg which are almost 10kg lighter than most metal lids making them quicker, easier and safer to remove.

Being made with non-conductive material they are ideal for installation near electrical structures. They are also transparent to radio waves.

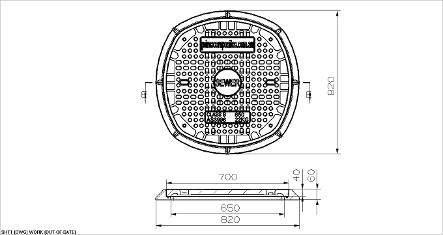

Based on consultation with many users we have produced our latest models with a clear opening of 650mm for safer access which is 50mm larger than most.

Our Class B & D access covers are made with a design life of 30years and do not attract scrap metal thieves. They maintain their dimensional stability and don’t dislodge.

Because of the manufacturing process and materials involved the access covers have tighter clearances which mean less chance of sewer odors.

The non-slip

design with its decorative floor finish remains practical for maintenance teams

without compromising style.

Our composite access covers are manufactured using a technologically advanced composite manufacturing process to create a highly engineered, incredibly strong composite product. The composite covers are available in a range of sizes and load ratings including sealed and unsealed.

Key benefits to Prime composite access covers over their steel and concrete counterparts cover an array of technological advances and cost savings including higher quality, improved safety, greater longevity, lower life cycle costs and a greatly reduced risk of theft. Due to the lower weight of the composite covers there is no need for cranes and other heavy-lifting equipment.

Unlike cast iron and steel manhole covers, the composite access covers are corrosion resistant and non-conductive. The composite covers have a unique skid resistant surface and will not spin-out, making it safe for road use purposes and designed as a “fit and forget” product for civil engineering applications. Unlike concrete manhole covers, the composite covers do not crack or crumble.

So if you need a lighter, stronger, safer cover at a competitive investment here it is.